USITT is in full swing on the other coast, and I am only a few days away from the next deadline on my book. Things are hopping around here! Here are some interesting things from around the web:

Since I couldn’t make it to USITT, I’ve tried using Storify for the first time to cull together some news and tidbits about it. Tell me what you think.

Local man hopes for a leg up to career in the movies! This is the story of a 47 year old man from Northern Ireland who was laid off from his job and decided to switch gears and learn how to make props for movies. Even if you don’t want to read the story, the picture at the top of the page is definitely worth a glance.

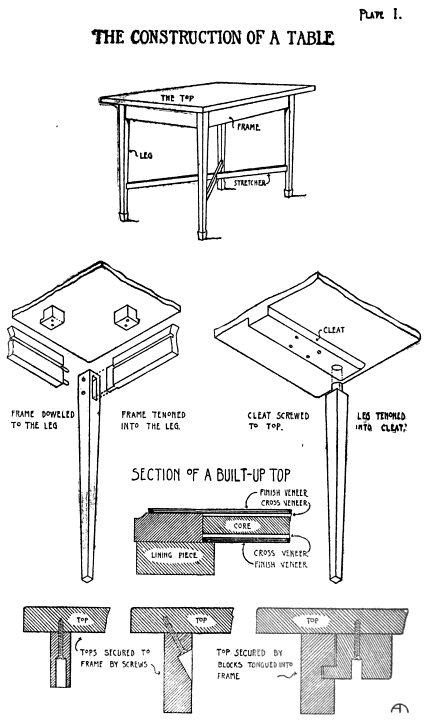

Do you like giant woodshops? Do you like Ron Swanson? Nick Offerman, who plays Ron on TV’s Parks and Rec, has an enviable woodshop, which he shows off in this video. Nick learned carpentry by working as a theatrical set carpenter, so he has his shop set up like a scenery shop. The things he builds, though, are a far cry from flats and platforms.

In this interesting article called “The Tool Works at Both Ends“, we learn how your brain adapts and remodels itself depending on what tasks we do throughout the day. If you sit in front of a computer all day, your brain becomes better at absorbing large amounts of text and processing it while multitasking on other thoughts. If you work in a carpentry shop all day, your brain becomes more adept at guiding your hands to use tools and imagining how pieces of wood would look assembled in your head. The article proposes a “mental crossfit” program to condition all the portions of your brain throughout the day. As props people, we probably have one of the best jobs as far as maintaining a good brain balance goes, in that we are constantly switching between tasks such as research, collaborating with team members, hands-on building and crafting, and abstract problem-solving.