To all of my American readers, I hope you have a Happy Thanksgiving this week! Brian Wolfe from Costume Armour sent me some photographs of a trick turkey they recently created, which seems apropos to the holiday.

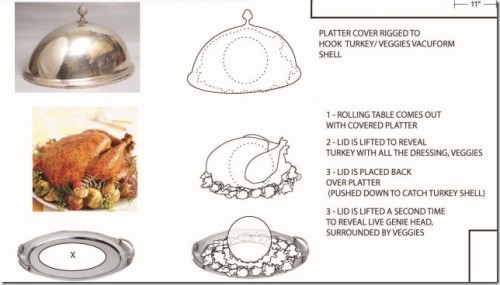

For this trick, a waiter needed to walk in with a food cart. He lifts the lid off of a covered tray revealing a delicious roast turkey. He replaces the lid, and the next time the lid is removed, the turkey is gone. Instead, an actor’s head is on the tray, and the actor begins to speak.

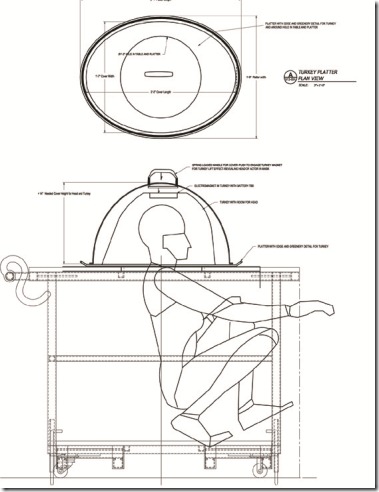

This is the drawing he shared with me:

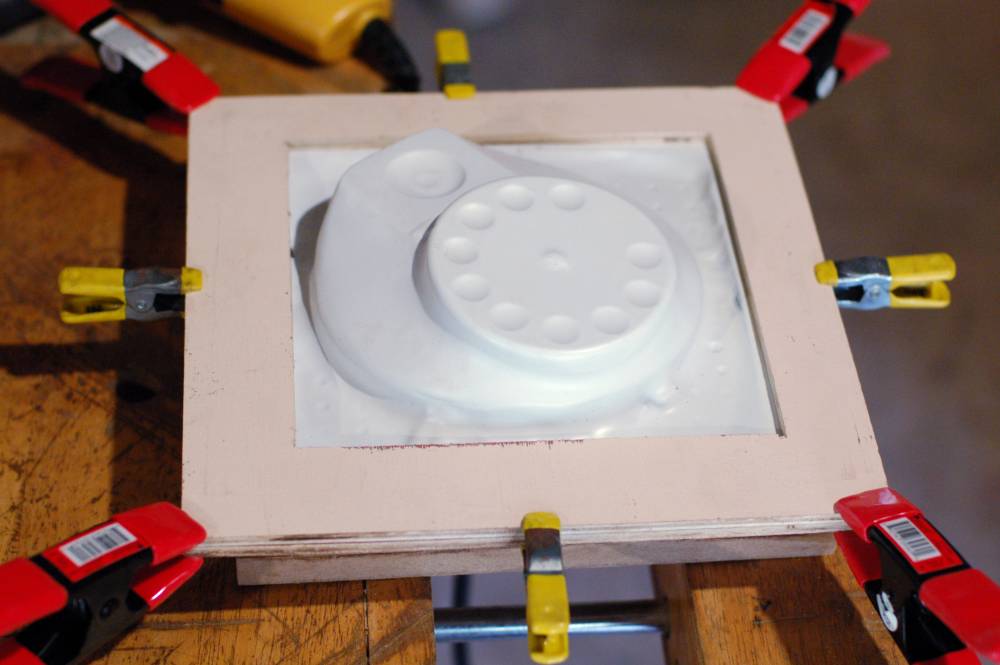

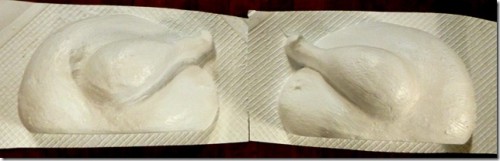

They needed a giant, oversized turkey with enough room inside to fit a head; it also needed to be light enough that it could be lifted along with the tray (you will see why in a minute). They had a rubber turkey in stock, but it was too small and heavy. So they decided to vacuum form a new one. They carved the turkey in foam, made a two-piece mold, and vacuum formed it in 0.04″ Kydex plastic.

They cut out the pieces, glued them together, and painted them. Next, they cut a large hole in the bottom:

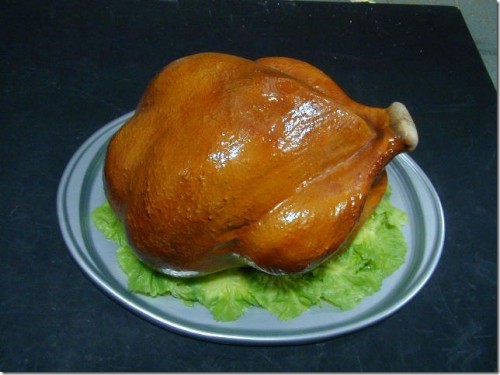

The tray was also vacuum formed, this time in a heavy 0.093″ Kydex plastic with a metallic finish. The bottom was formed over a wooden mold, while the lid used a plaster mold. They also added some artificial lettuce which was bought.

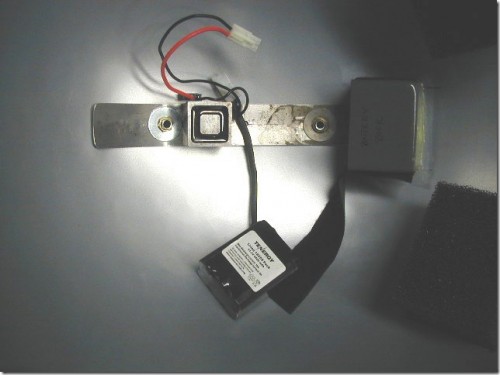

A brass drawer pull completed the look to the lid. The small black rectangle next to it in the photograph below is a small toggle switch:

When the waiter flips this switch, a small battery-powered electromagnet turns on (shown in the next photograph). The turkey had a small piece of flat steel hidden on top which is grabbed by this magnet. So when the magnet is on and the tray lid is lifted, the turkey travels along with it, hidden from the audience’s view.

The diagram below illustrates how the whole trick was set up. I’ve seen this same basic principle carried out in a number of different ways, but the combination of the hollow turkey and electromagnet makes this execution especially elegant; you can control whether the turkey or head is visible simply by the flick of a switch. The actor underneath does not have to do anything.

Hope you enjoyed this! Have a Happy Thanksgiving!