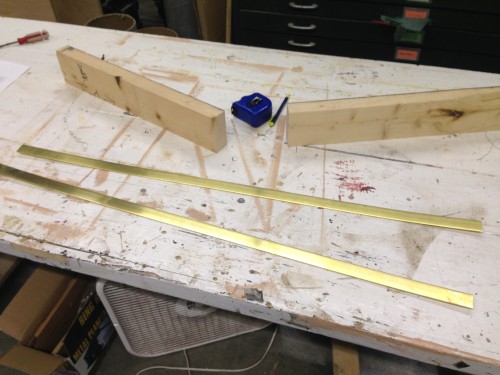

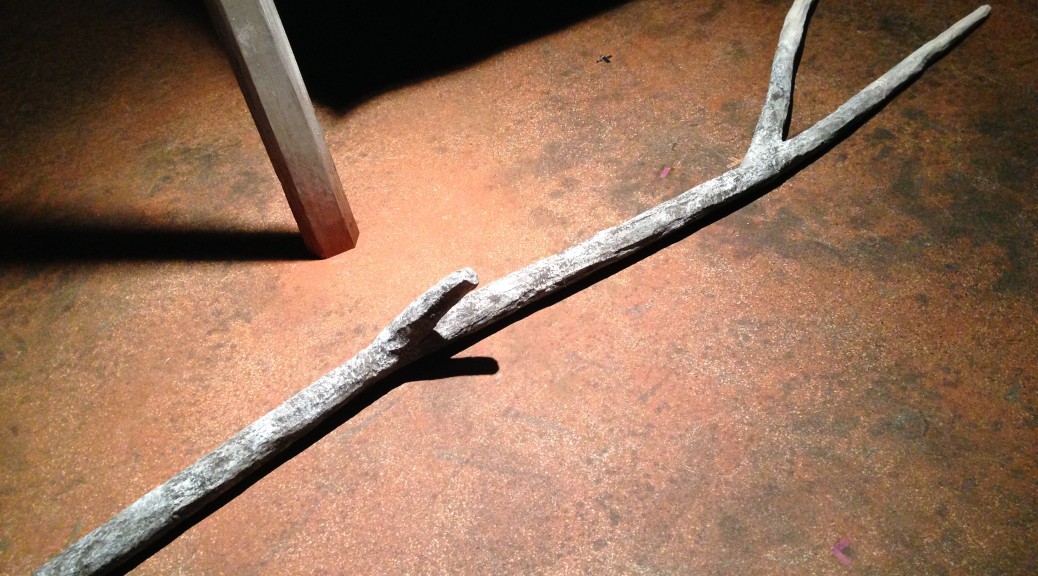

For the holiday show at Triad Stage in Greensboro, we remounted the production of Snow Queen we made last year. I had built a number of puppets for the show which only requited minor adjustments and maintenance, but I wanted to completely rebuilt the crow puppet. He went through so many iterations and modifications last year as we tried to discover what worked best, so the end result was a hodge-podge of cobbled-together parts and mechanisms. He was difficult to maintain and he broke frequently. Â When I knew we were remounting this production, I budgeted in a complete rebuild of the crow.This time around, I was able to order more appropriate and precise materials, rather than assembling it with whatever I could find at the Home Depot.

I made a video showing the inner mechanisms of the puppet and how it is operated:

You can compare that to the puppet I made last year. The rod is now two pieces of aluminum which sleeve together, rather than two pieces of PVC pipe which bend and wobble. I abstained from using any string this year, which always stretched and lost tension, or broke completely. Most importantly, I planned the construction out so the parts were completely modular, and everything could be taken apart with bolts, screws or Velcro. The crow last year was a bit of a nightmare when it came to maintenance, because a lot of the pieces were permanently attached to each other, so it practically required laparoscopic surgery to fix anything that broke.