Put ten prop makers in a room and you’ll get ten different stories of how they became a prop maker (you’d also get one hell of a party). I thought I would share my own convoluted path of how I have gotten here.

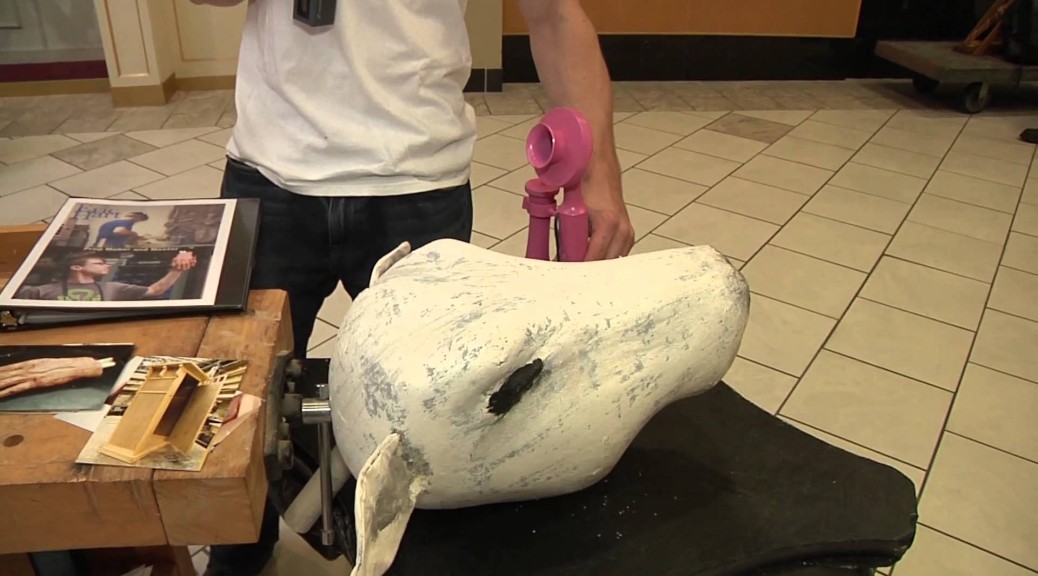

My parents are both artists: potters by trade. They fed my brother and I a steady diet of art supplies growing up. We would transform all sorts of boxes and other random objects into vehicles and machines for our stuffed animals to use. One of our favorite toys was He-Man. I remember desperately wanting the Castle Grayskull playset when it first came out. Of course, a toy that large was far too expensive; nonetheless, we kept pleading. Finally, my dad started building his own version of Castle Grayskull for us. I think he used chicken wire over a wooden base, coated with a mix of papier-mâché and plaster.

They often gave us bits of clay to sculpt and shape on our own. When I got old enough and wanted a job, my dad put me to work making production molds for his cast pieces, and then casting the pieces.

In junior high school, we still had this class called “Industrial Artsâ€, in which twelve-year-old children are allowed to cut wood on a bandsaw and squirt hot plastic into injection molds. I remember the feeling that was awakened in me when I cut a fancy letter “E†out of a piece of pine in that class. It was a two-part revelation; first, I discovered how these wooden objects were created, and second, that I possessed the ability to create them. I also cast a piece of iron in green sand, doing every part of it except the actual pouring of the molten metal. It gives a kid a lot of confidence to have a cast iron object and be able to say “I made that.â€

In my first year of high school, after choosing all the necessary classes for my preparation to be a college student, I found one free period. A buddy and I convinced each other to take wood shop. During the first half of the year we studied and practiced drafting. The second half, we built a bookcase. From scratch. We had to draft the piece out and make a cut-list, select and buy our lumber, plane the surfaces, join the edges, cut the pieces to size, make the joinery, assemble it, and apply the finish. It was all pine wood, with no plywood or MDF; the back was made with a whole bunch of boards tongue-and-grooved together. I still have that bookcase.

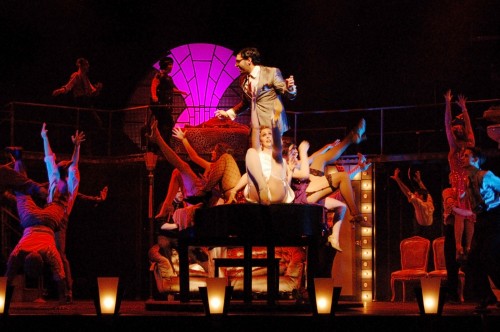

I began my undergraduate career as an engineer, but grew bored with the lack of hands-on work I thought it would entail. I was living and working with a lot of the theatre and film kids. We had a film club, which consisted of a bunch of us running around filming goofy things with a camera. I thought some theatre classes would help me make better films. Along the way, I grew to appreciate theatre more than film, and ended up graduating with a degree in theatre and an emphasis in scenic design.

After a few years of working as a stagehand, carpenter and electrician, I went back to graduate school for scenic design. After the first year, I got a summer job at the Santa Fe Opera as a props carpenter, building furniture and other large items. That was when it kind of clicked in my head that making props was what I really loved. It was the combination of technical skills and creative thinking in the context of a collaborative art form that really drew me in. The variety of daily tasks kept me engaged in a way that a job where I built the same thing over and over again would leave me bored.