One of the trick props we needed for The Book of Grace was a phone which John Doman smashed during every performance. We decided that the phone receiver would remain real, but the part it hung on would be cast from plaster. It would all hang on a wooden base, and a collection of “phone innards” will be held inside the plaster part, so when it broke, an assortment of metal bells, chip-boards, and other electronic components would be left hanging on the wall.

We made a two-part silicone mold of the phone. Making a two-part silicone mold is beyond the scope of today’s post. However, I did get a photograph before the pouring of the first part. At this point, Natalie Taylor Hart took over the project.

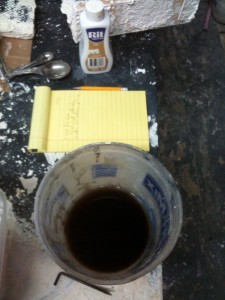

Normally, the next step is to make the second half of the mold from the back of the phone. In this case, the shape of the back was far more complicated than what we needed, and we were worried the plaster cast would be too thin. So we took the first part of the mold and built up the thickness we wanted to achieve out of Klean Klay. The Klean Klay is the yellow substance in the photograph above, and remains flexible like plastiline. It also does not contain sulphur, which reacts with the silicone mold-making compound. The mold still needed some tweaking, so Natalie carved directly on the silicone to perfect it.

We wanted the color of the phone receiver to match the back part, which was the sort of taupe that most appliances from the late twentieth century came in. When the plaster phone gets smashed, the broken edges would show up white. Thus, we needed to dye the plaster while it was still in liquid form. Natalie found that a tablespoon of Rit tan dye in the mix made the best color match.

Natalie sifted the plaster into the water until tiny islands of plaster began to form on the surface. Once she had made a few phones, she had the exact measurements of both plaster and water marked down.

Next, she let the plaster sit in the water for about 30 seconds. “Wetting” the plaster allows it to mix more thoroughly.

With such a small amount, she mixed it by hand. This also gave her a tactile way to ensure all the lumps were worked out of the mix.

Natalie discovered the best way to pour this particular mold was to slosh plaster over the top half before putting it together. It was important to get plaster in all the cracks and crevices or the strength would be compromised.

The phones set up overnight, but they actually took two to three days to fully dry. We could not get any kind of adhesive to keep the plaster parts onto the bases until all the moisture was completely out. We ended up needing around 40-50 phones for the run of the show, but since we could cast more than one a day, we could make them throughout the run rather than all at once.

Finally, here’s a video showing the end result. This was taken earlier with a different phone model, before they changed it to the slimmer model.