Suppose you want to divide one foot into four parts: that is three inches. Divide a foot into three parts and you have four inches. Divide a meter into four parts: each part is 25 centimeters. Divide it into three parts and you are left with 33.33… cm.

The same is true with liquid and dry measurements. Take a cup. Now double it and you have a pint. Double it again and you have a quart. Take a gallon and divide in four; that’s a quart. Divide a liter into four parts, and you have to call it either 2.5 deciliters or 250 centiliters.

Look at a clock; it has sixty seconds in every minute, and sixty minutes in every hour. You can divide a minute in half, thirds, quarters, fifths, or sixths and in every case, you are left with a whole number of seconds. No fractions or decimals.

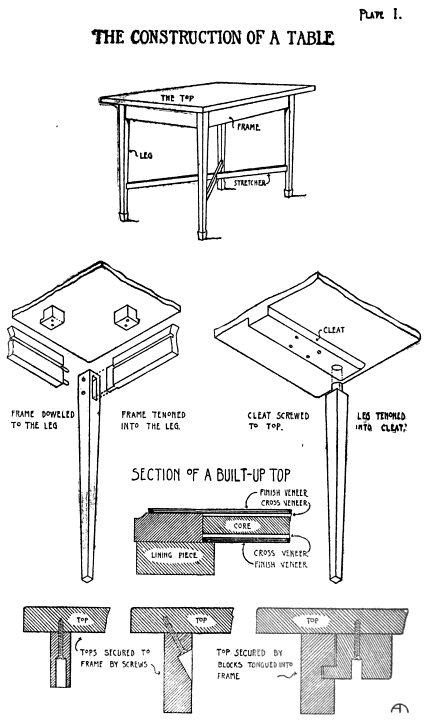

Metric may be good for scientific and technical measurements with things that increase by orders of magnitude. For example, hard drive memory started out with bytes, than kilobytes, followed by megabytes, gigabytes and now terabytes. But when dealing with carpentry and recipes and other measurements used in the construction of props, you are not having to convert between units which are one hundred or one thousand times larger than other units. You are dividing things into halves and quarters and thirds. You want to be able to take a measurement with a ruler which gives you one or two whole numbers and a fraction. It is so much easier to say “this prop is one foot and three inches tall, two feet and five inches long, and three quarters of an inch thick” than it is to say “this prop is 38.1 centimeters tall, 73.7 centimeters long, and 19 millimeters thick.” Furthermore, when you look at a tape measure, the hash marks for the fractions of an inch are all different sizes, so you can easily see whether you are at 1/4 or 5/16. With a metric tape measure, you have ten tiny divisions per centimeter, all at the same height. Is that .7 cm or .8? Who knows! (Of course, the greatest sin is a tape measure with both metric and customary units.)

The system of inches and feet were developed from commonly experienced physical objects, like a human thumb and a human foot. Their subdivisions were developed to measure commonly constructed objects for everyday use. This is what we deal with in props; the construction of everyday items on a human scale. A meter, on the other hand, was derived as a fraction of the Earth’s diameter. How much more sense does it make to say “this bench should be as long as three of my feet” than it is to say “this bench should be large enough so that 3,187,000 of them will fit end-to-end from one side of the planet to the other, going through the center”? Balderdash!

Metric is a centrally-designed hierarchical system which is applied to the measurement of everything conceivable, while customary units are a collection of localized systems specifically altered to the items and entities being measured. It may be funny to dig up archaic names of measurements to ask rhetorical questions like “how many hogsheads in a morgen”. In reality though, you will never need to convert the measurement of a cask of wine to the measurement for a plot of land. As an aside, archaic units are not limited to the customary system; does anyone in metric still use a stère?

It may be tricky to calculate how many inches are in a mile, but you rarely need to use that conversion in day-to-day life. Finally, despite the often touted ease of converting from nanograms to kilograms to megagrams, scientists have settled on essentially using the kilogram to measure the mass of everything, from the sun to an electron. No need to convert anything!

This is not so much a case against metric, but an appeal for hybrid systems and specificity in measurements to the task at hand. There is no harm done if I build a bench using inches and feet while biologists measure the volume of a cell in micrometers. I don’t wear the same outfit as a biologist, and a biologist doesn’t use the same tools and machines as a props artisan. That would be absurd. Neither of us have to convert the volume of a cell to the height of a chair. That would be even more absurd. Both of us using the same system of measurements? That’s the absurdest.