A few weeks ago, I visited Jim Smith out at RC4Â Wireless. I was working on a magazine article about Cirque du Soleil’s new show, Kurios, and their use of RC4 Wireless units. Since Jim was just an hour down the road from me, I thought I’d swing by and see how they’re made.

If you’ve never seen or used an RC4 Wireless dimmer, think of a small box that lets you control electrical devices from your theater’s lightboard. So, if you wanted a flashlight, or a lantern to turn on and off during a light cue, rather then having the actor use the switch on the prop itself, these are one of the wireless dimmers that can make that happen.

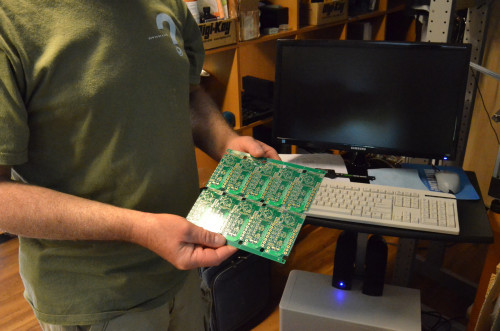

When I got to his workshop and he showed me around, what surprised me most was the fact that he was building every single unit right there by himself. He starts with a printed circuit board, or PCB. These he gets made up at a factory, but then he prints the circuit paths on in his shop.

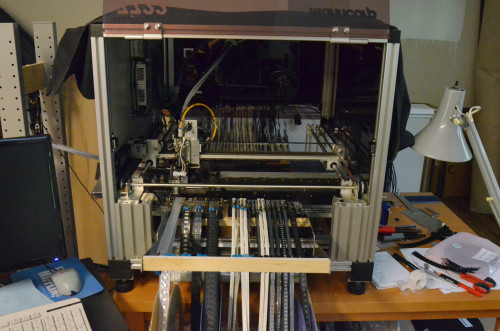

Next up, the boards go into his pick-and-place machine. Various components come on reels of “tape”. These are fed into the machine, which grabs what it needs, and places it exactly where it needs to go on the circuit board.

Before he got the pick-and-place machine, he was placing every component onto the board and soldering them in place by hand. Not only does the pick-and-place machine allow him to work much faster, but it allows him to use much smaller components. At a certain size, he has to use tweezers just to handle the components and a magnifying glass to see where to solder. He cannot physically work with anything smaller. With the machine, he can use smaller components, which mean smaller RC4 units overall.

Once all the surface mounted components are in place, he brings them over to an oven, which bakes the solder and locks everything in place.

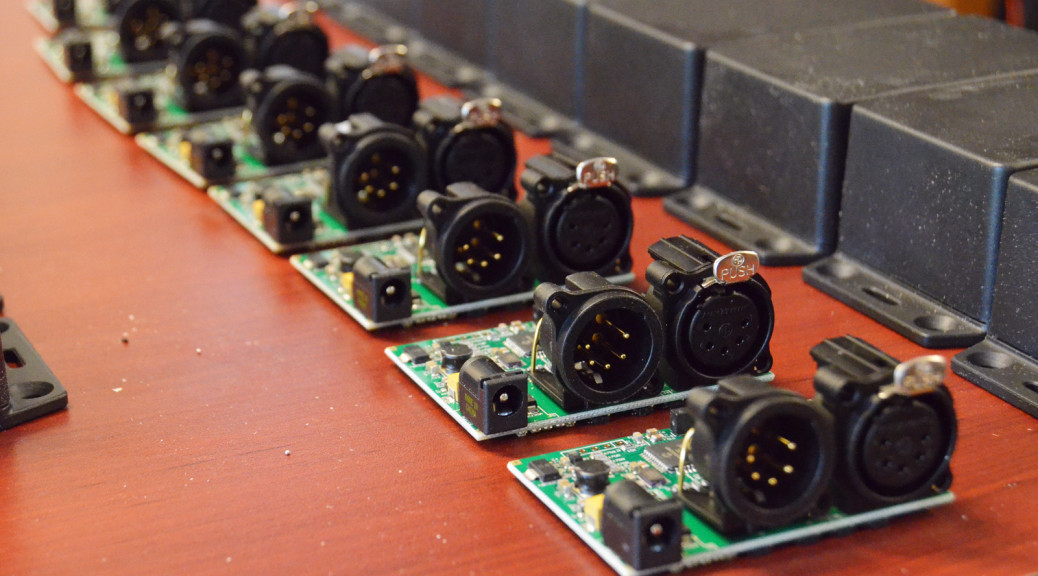

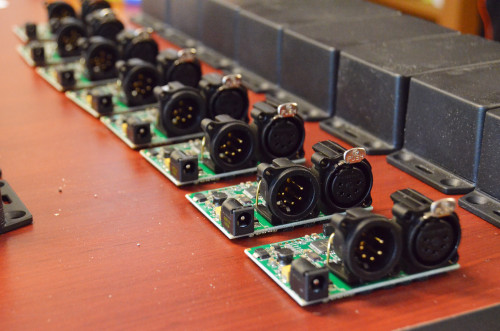

He then adds the through-mount components. These are things like the DMX connectors or switches or anything that will be poked and prodded by a user. Using through-mounts gives them a strong mechanical connection. It’s basically like bolting the pieces on, where the pick-and-place machine can be thought of as “gluing” the pieces on.

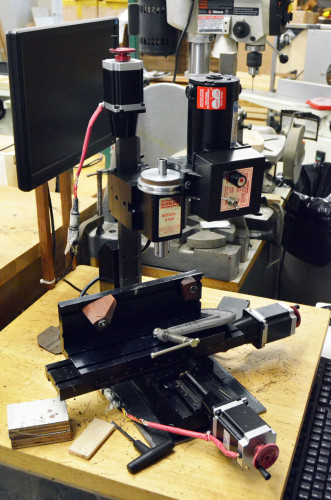

The cases he uses are standard cases that he can buy in bulk. He then puts them in his CNC milling machine to cut out all the holes for connectors, switches and mounting hardware. The finished units then head inside his house where they get tested, programmed, labelled and packed. From there, they head off to companies like Cirque, where they are used for… well, you’ll have to wait for my magazine article to come out to see what they are used for.