One of my recent projects was a circus platform (though its more of a stool). It’s a very simple-looking shape, but it’s a little tricky to pull off. Think of the bottom half of a cone and that is what I had to build.

I started off making the structure for the platform. It had two circles of plywood, joined by a few lengths of plywood cut at a taper. The circles also had their edgers beveled to match the angles of the taper.

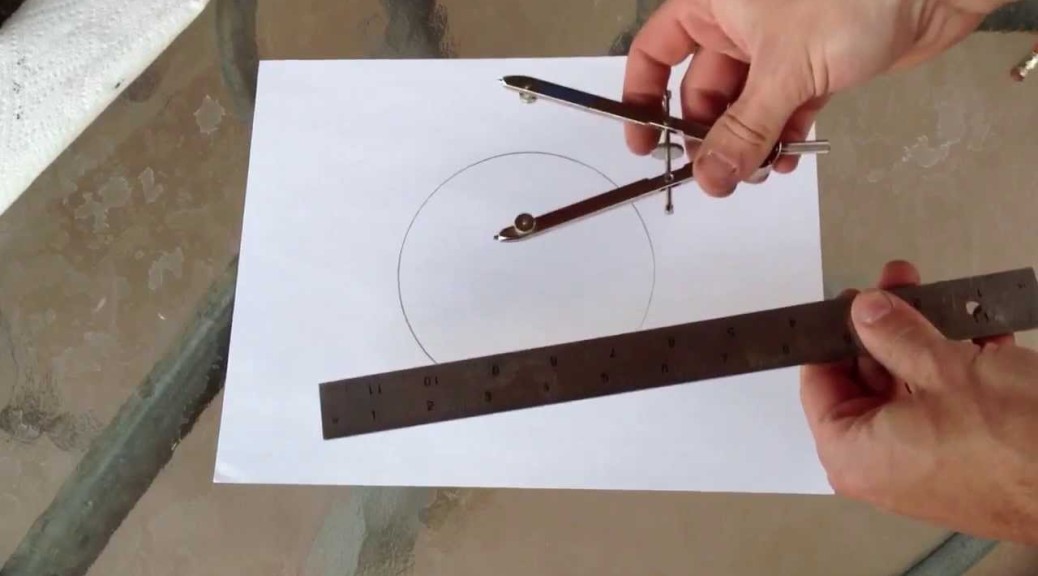

Adding the wiggle wood skin was one of the tricky parts. With a tapered shape like this, you can’t just wrap the wiggle wood straight around it. It actually requires a radiating arc shape like in the photograph above. I only rough cut the shape above, leaving a bit of extra all around that I can trim off once it is attached.

The top was easy to trim, as it wanted to be flush to the plywood circle seat. The bottom was a different matter; it needed to extend past the bottom circle, since it was getting castered, and the wiggle wood would hide the casters. I set up a horizontal routing jig so I could cut the wiggle wood to a consistent height all around its circumference.

I had cut four wholes in the bottom of the stool, and now that it was time to attach the casters, I had access to get my hand inside and bolt them on. That’s planning ahead!

And that’s my circus platform! The photo above already has some paint on it, though the final prop will have much more.