Our final opera at this past season of the Santa Fe Opera was “Oscar”, a world premiere based on Oscar Wilde. I made a bench for it. It was a simple bench, and the legs were purchased rather than made by us, but it was all solid alder wood, and the end result was quite attractive.

I picked up a truckload of alder from the local lumber store, and planed and jointed some boards for the seat. The seat was a full inch thick, so it was quite hefty. After gluing them together, I rounded off the corners and routed a round-over along the whole circumference.

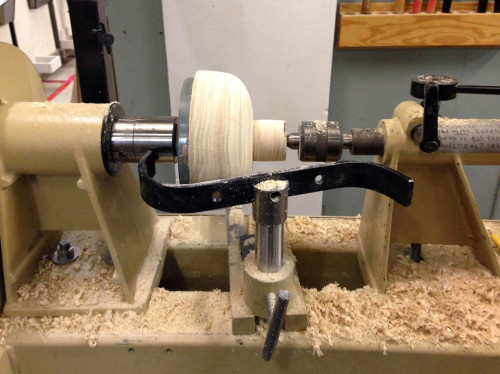

The trickiest part were the bars on either side which stood on top of the seat. I turned them out of the same alder I had bought. I then constructed a jig for drilling the holes. The jig allowed me to drill the hole exactly perpendicular to the bar, as well as to place the hole directly in the center (width-wise) of the bar. I also marked the bars so I could drill both holes along the same line.

Next, I had to line up the holes on the bars with the holes on the seat. The dowels connecting the bars to the bench were also turned by me out of alder. They ran through the top into the legs, so you could pick the bench up by the bars very securely.

For an extra touch, I fabricated the half-round molding along the bottom of the apron from the same alder I used on the rest of the bench. Since the legs we bought were also alder, this meant the entire bench was solid alder, and it would have a consistent appearance when stained.

The final bench was stained by our paint department; I had actually constructed two (the one above and a much longer one), but the second one was cut. Again, it was fairly simple, and the legs were not turned by me, but working in solid wood is always fun and interesting.