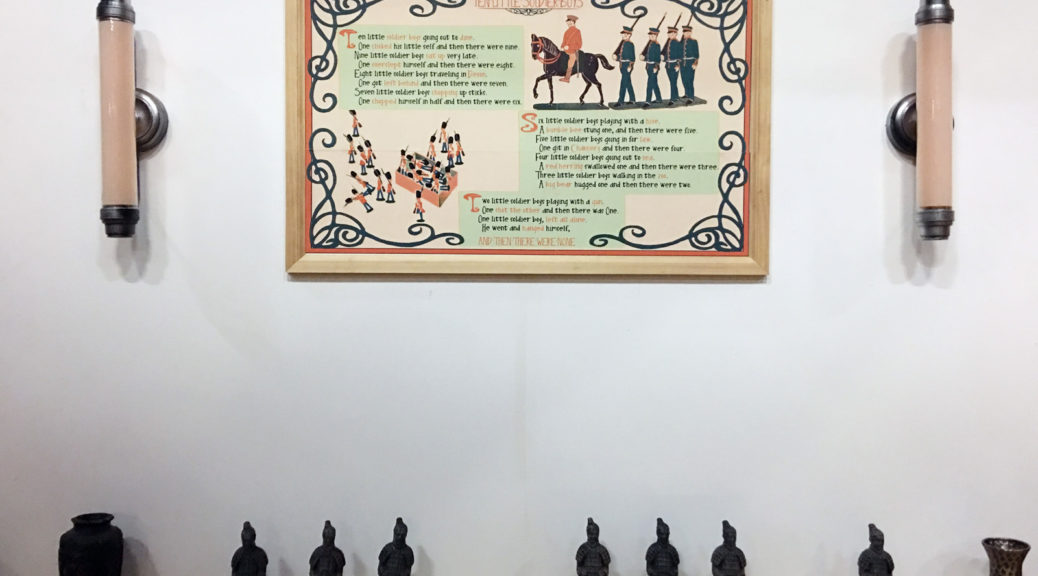

We recently opened “And Then There Were None” at Triad Stage in Greensboro, NC. Agatha Christie’s classic murder mystery takes place in 1930’s England in a sleek, unique seaside home. Robin Vest’s scenic design gave us a sparse, Art Deco-inspired interior populated with a few trappings of a world traveler.

Flanking the fireplace were two tube sconces. Finding an appropriate vintage pair was proving to be too expensive, so I decided to make them.

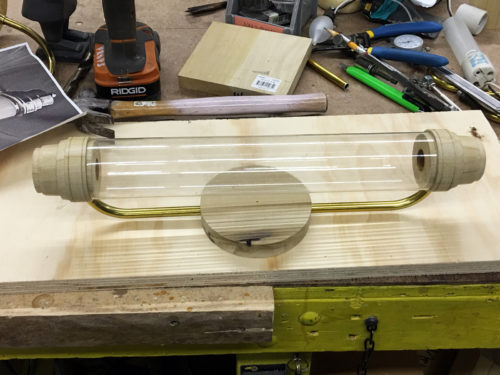

I turned the top and bottom caps out of poplar on my lathe. I think this was the first project I personally used the shop’s lathe for, even though I purchased it last year.

I bought some plastic mailing tubes for the lamp shades. Glass tubes were pricey and difficult to find in the right size. I measured their inner and outer diameter and turned the end caps so the tubes would slide onto them snugly.

I needed some curved metal arms to hold the end caps, and they needed to be hollow so I could feed the wires through. I had some spare chandelier arms in my bin of lamp parts which I cut to size. It was a lot easier than attempting to bend a metal tube without kinking it.

Above is all the pieces mostly assembled. I drilled holes in the end caps to feed the metal arms in, and used epoxy clay to secure them. I cut a disc out of poplar for the wall plate and drilled two more holes to hold the metal arms. The bottom arm was epoxied in place, but the top arm was only bolted to the plate. I wanted to be able to disassemble the sconce in case I needed access to the interior of the tube.

I added a decorative disc of metal to the wall plates that also came from my lamp parts bin, which you can see in subsequent photos.

With all the pieces fitting together as they should, and sanded smooth, I took them apart and painted them. I used a variety of spray cans. First was a sandable primer, followed by two coats of gloss black, than two very light coats of chrome, finished off with an extremely light dusting of the gloss black again. I only waited about half an hour between coats, so the whole process was finished in a morning. If you wait too long between coats, the paint may develop that dreaded “orange peel” appearance.

Because the tubes were plastic, I could not use any incandescent or halogen bulbs. The heat would build up and melt everything. I bought some warm white LED tape and mounted it to a small stick of wood to hold it straight against the back of the tube. The wires ran through the arms and out the back to a transformer and DMX controller, where it could hook up to the theater’s light board.

I cut a piece of thick vellum to line the inside of the tube and provide some diffusion.

Here they are, fully assembled and ready to go. Even though these LEDs were the warmest white I could find, they were much cooler than every other practical light fixture on stage when we got in the space. I opened the tubes and added a piece of orange gel from my lighting designer to warm them up.

Here they are on stage. While they are very similar to modern tube sconces, they have just enough subtle period detail to help create the world on stage.

These sconces are so lit.

Damn! Ingenious and beautiful

The trick to bending copper or aluminum tubing is to fill the tube with sand before bending, It will not kink . We use to do it with rigid polystyrene tubes up to 1.250″, then heat bend some very tight bends.

A 75 yo propman.