It’s another Friday, and another September. This always seems like the busiest time of the year for the whole entertainment industry. Some of you may have gotten a four-day week this past week, but for most of us, it was an eight-day week. So take a seat, relax, and enjoy these links for a few minutes:

Huffington Post has an interview with props master Peter Bankins. Bankins has been a prop master in film for the past 25 years, working on movies such as Young Guns, Grumpier Old Men, Erin Brockovitch and many more.

On the other side of the pond, Farfetch has a short photo essay called “Our Day With Thomas Petherick“. Petherick is a young prop maker and set designer working mainly on fashion photography shoots.

Bill Doran and his wife created a fairly detailed set of armor and weapons from the video game Skyrim for this year’s Dragon Con. He details the lengthy build process as they fashion parts out of wood, EVA foam, Worbla, resin and more.

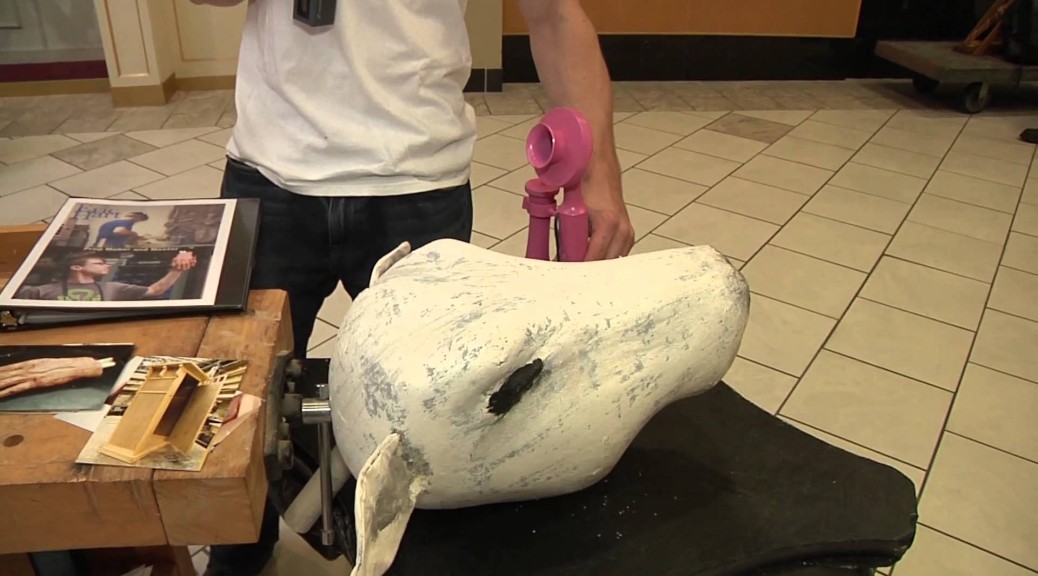

Finally, here is a familiar face; I was displaying some of my props at last month’s Burlington Mini Maker Faire. Coffey Productions was going around filming the various exhibits, and shot this video of me talking about my props and my book. Check it out!